Ai-enabledDesign for Additive Manufacturing

An online Short-Term Training Program (STTP) exploring the tools and techniques design for additive manufacturuing.

About DfAM 2025

Artificial Intelligence (AI) has become an essential tool in optimizing and generating advanced designs that enhance functional integration, part geometry, product structure, and material stiffness. Modern designers and engineers face the challenge of mastering AI-driven methods and algorithms for Design for Additive Manufacturing (AI DfAM).

This session offers a hands-on approach to applying design principles and AI algorithms to either improve existing designs or create entirely new ones at a significantly lower cost than traditional methods. Industries such as Automotive, Aerospace, Healthcare, and Consumer Electronics are rapidly adopting AI-DfAM to unlock unprecedented design freedom. Participants will gain practical insights into early-stage design problem-solving and learn to leverage the full potential of metal and polymer additive manufacturing processes.

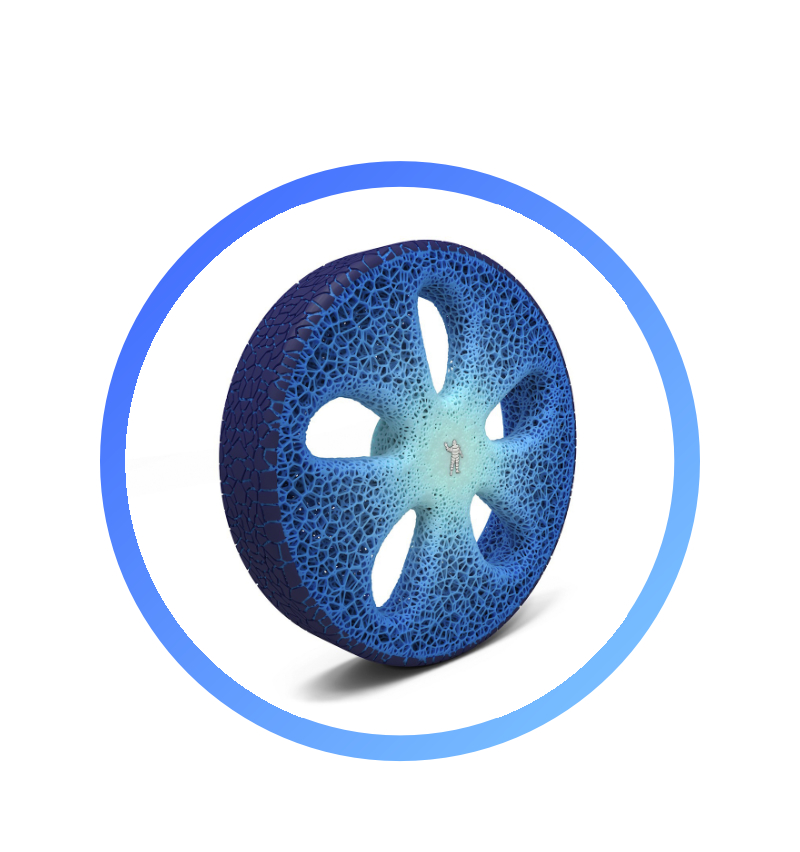

Design Freedom

Explore the unprecedented design freedom offered by additive manufacturing technologies.

Optimization

Learn techniques to optimize existing designs for additive manufacturing processes.

Innovation

Discover innovative approaches to design that leverage the capabilities of 3D printing.

Program Highlights

An immersive online experience designed to provide comprehensive knowledge and hands-on skills in additive manufacturing through interactive sessions.

STTP List of Topics

Explore the comprehensive curriculum of advanced topics covered in the DfAM 2025 program.

Multi-Materials

Design shells and assign material for realizing full-color multi-material products with digital materials.

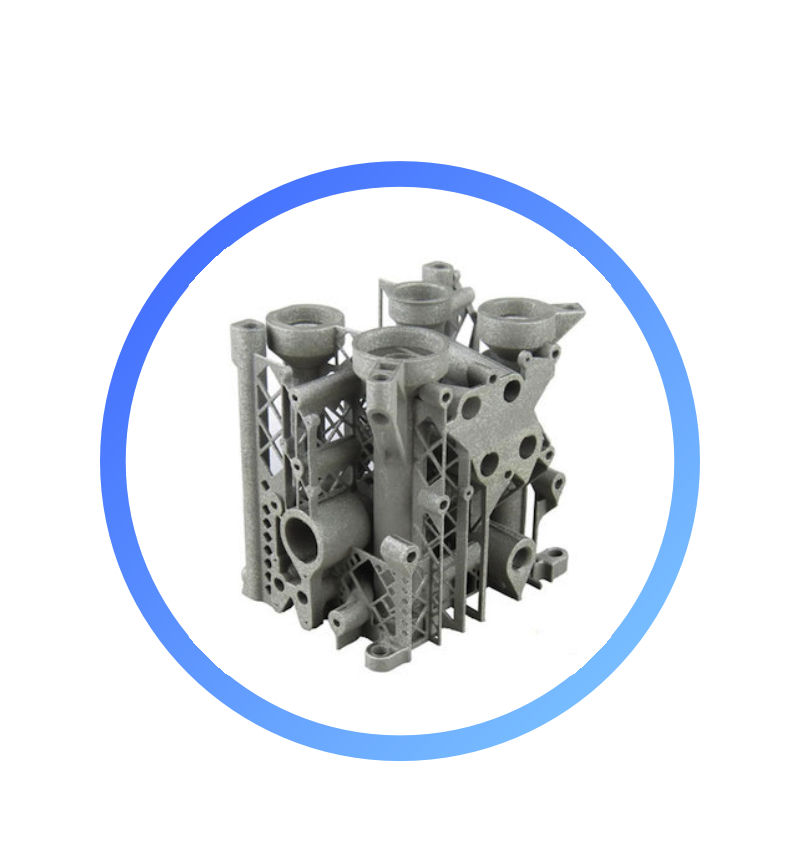

Functional Integration

Integrate as many technical functions as possible into as few parts as possible to take advantage of design freedom in AM.

Mass Customization

Customize the design for personalization and flexibility and at the same time achieve the low cost of mass production.

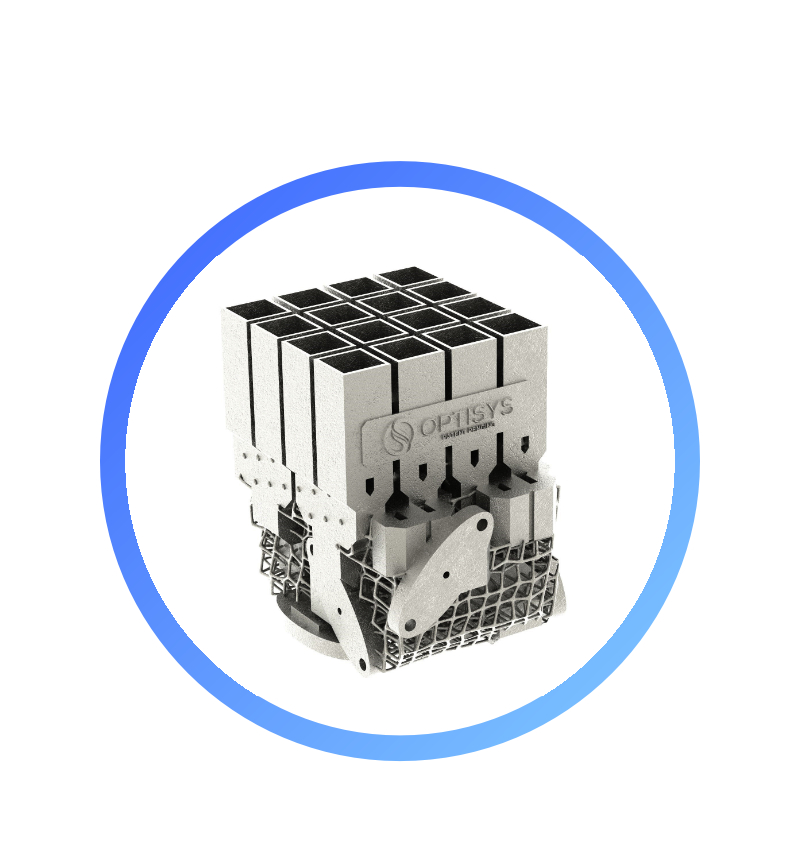

Part Consolidation

Achieve part count reduction for ease of assembly and simplify the product design yet introduce more shape complexity.

Light-Weighting

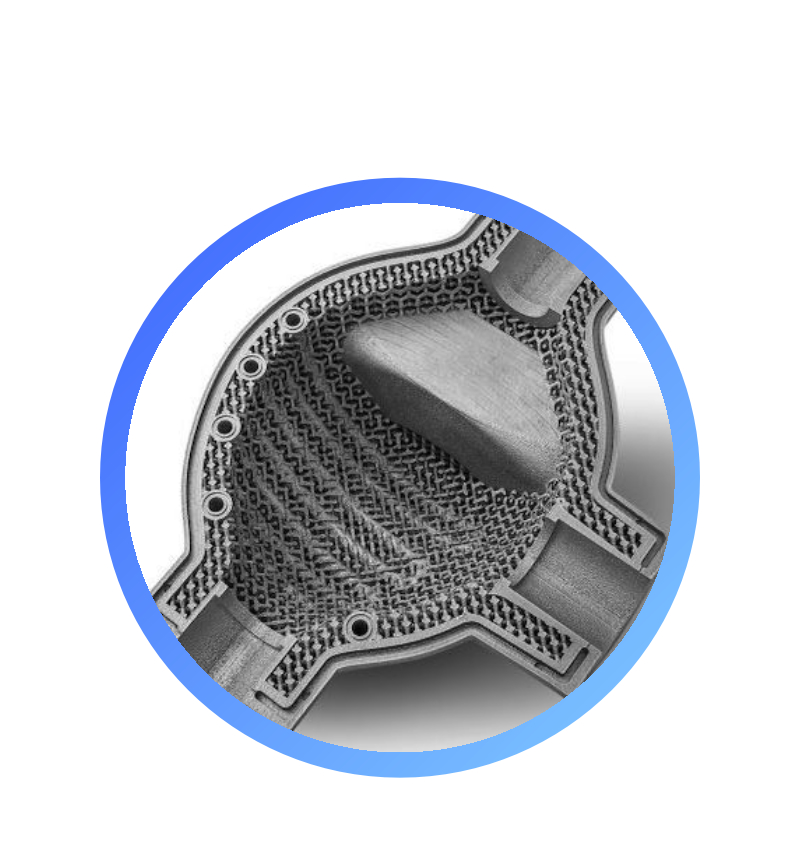

Introduce intricate lattice structures with structural optimization to reduce weight and efficiency of mobility solutions.

Heterogeneous Modeling

Design multi-material and gradient structures to take advantage of possible material complexity in AM.

Generative Design

Iterative design process that outputs optimized design that meets real-world manufacturing constraints.

Hierarchical Structures

Design repeating structures in macro, meso, micro, and nano scales to get superior performance.

Topology Optimization

Optimize material layout within a given space, for a given set of loads, boundary conditions and constraints.

All topics include both theoretical knowledge and hands-on practical sessions

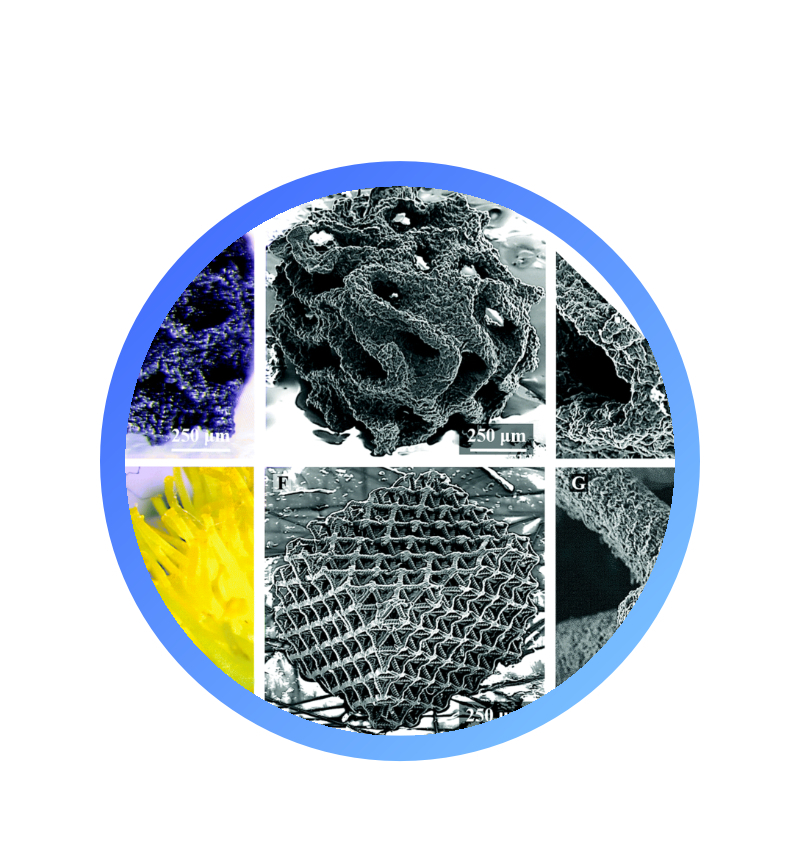

Previous Event Glimpses

Discover the innovative projects and technologies you'll explore during the DfAM 2025 program.

Registration Information

Secure your spot in this exclusive training program. Limited seats available.

*Includes SBI processing fees

- Access to all sessions

- Workshop materials

- Certificate of participation

*Includes SBI processing fees

- Access to all sessions

- Workshop materials

- Certificate of participation

- Networking opportunities

*Includes SBI processing fees

- Access to all sessions

- Workshop materials

- Certificate of participation

- Networking opportunities

- Industry-specific insights

Registration Deadline

Time is Running Out

Secure your spot in the DfAM 2025 program before registration closes. Limited seats available!

Program Resources

Access preparatory materials and resources to enhance your learning experience during the program.

Program Brochure

Comprehensive overview of the DfAM 2025 program, including schedule, topics, and speakers.

Download PDFIntroduction to DfAM

Introductory reading material on Design for Additive Manufacturing principles and applications.

Read ArticleCase Studies Collection

Real-world examples of successful DfAM implementation across various industries.

Download PDFOrganizing Institute

Learn about the prestigious institution hosting the DfAM 2025 program.

IIITDM Kancheepuram

An Institute of national importance established by Ministry of Education

Institute of National Importance

Established in 2007

Diverse Programs

About IIITDM Kancheepuram

IIITDM Kancheepuram was established in the year 2007 to focus on Information Technology enabled Design and Manufacturing education for catering to the needs of the industry.

It is one of the Institutes of National importance, fully funded by MHRD, Govt. of India. The institute offers four undergraduate programs, five dual degree programs, four post graduate programs and doctoral programs.

The courses are more oriented towards design and manufacturing, where the students get specialized in their domain with design as a connecting thread.

Department of Mechanical Engineering

The Department of Mechanical Engineering at IIITDM Kancheepuram is dedicated to advancing manufacturing technologies through research, education, and industry collaboration. The center focuses on additive manufacturing, smart materials, and digital manufacturing processes.

Research Areas

- • Additive Manufacturing

- • Design Optimization

- • Smart Materials

- • Digital Manufacturing

Facilities

- • Advanced 3D Printers

- • Material Testing Lab

- • Design Software Suite

- • Simulation Tools